The constant increasing quality requirements of its customers and the utmost competitiveness of global markets have deeply pointed out the will of Trafilspec-ITS to look for a continuous improvement and an always precise planning of its investments in order to reach a complete satisfaction of its customers in term of quality, on-time deliveries and high professionalism either in the projecting stage or after-sale services.

Our modern and qualified equipments allow us to reach high quality products and precision which represent an important guarantee for our customers.

The aim of achieving always better products from a quality and performing point of view has led to the setting up of Trafiltest S.r.l., a laboratory operating in full autonomy, featuring a complete range of equipments designed to ensure the final quality of the products of Trafilspec-ITS.

The testing effected in our laboratory are the following:

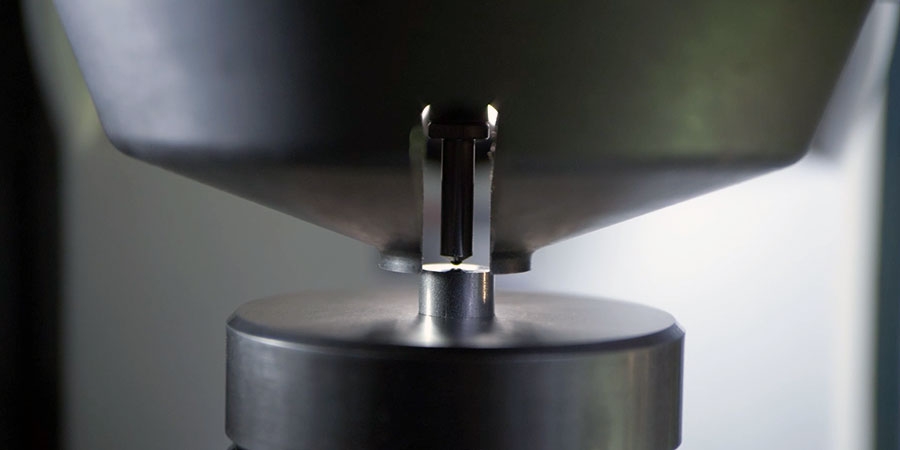

- Brinnel, Rockwell and Vickers hardness: this is the resistance that a material opposes to let it scratch, penetrate or get it into, from an harder material; this represents the attitude of a mechanical component to support high load and wear-resistance.

- Tensile testing (Rm, Rp 0,2, A5%): this is the capacity of the material to support high loads, coming from its employment.

- Metallographic examinations: the metallographic test allows to check structure, inclusions and decarburization.

- Spectrometer analysis: the spectrometer test allows to state the chemical analyses of the steel and trace the charge it belongs to.

Download 2014 Catalogue

Download 2014 Catalogue