Our cutting edge systems, designed for excellent energy performance, reliability and uniformity, enable us to treat a vast range of materials.

Trafilspec ITS is equipped with modern, efficient plant, designed to satisfy even the most demanding requirements.

One of these is the STC (Short Time Cycle) furnace, one of the first in Europe for horizontal chamber controlled atmosphere heat treatment.

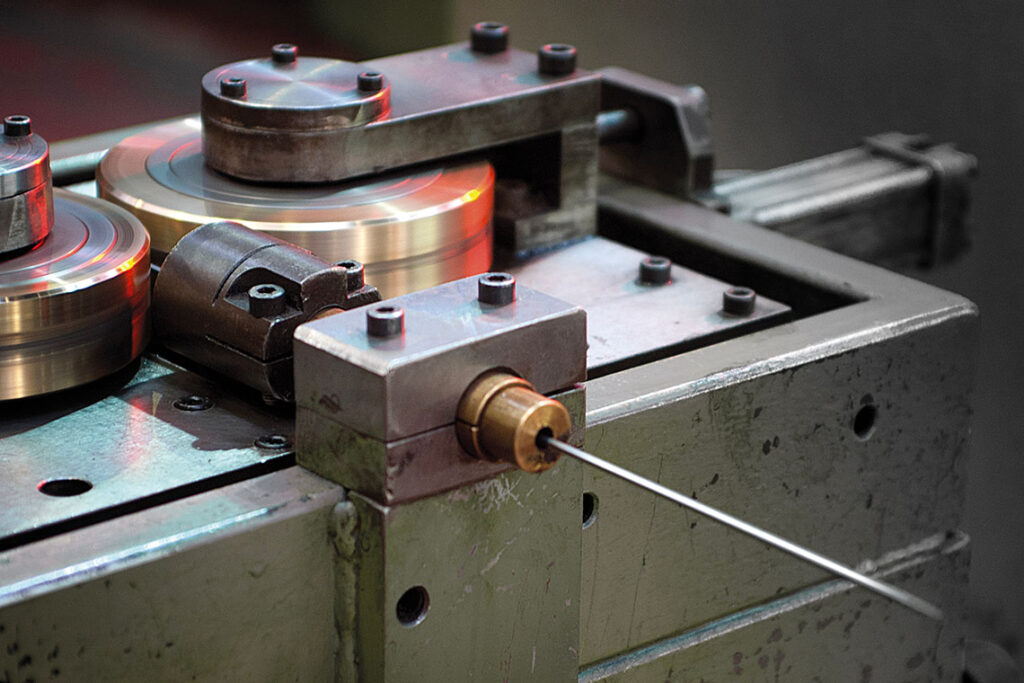

This technology enables Trafilspec ITS to run spheroidizing annealing cycles in a very short time and with excellent control of thermal uniformity, thus achieving a metallographic structure which is ideally suited to mechanical processing.

Trafilspec ITS offers a variety of heat treatments, each of which responds to a particular requirement of our clients’ applications:

Spheroidizing annealing

This, done in horizontal furnaces in a controlled atmosphere, enables us to achieve a uniform spheroidal structure which is ideally suited to further mechanical processing.

Normalising and stress relief

These treatments restore the uniformity of the microstructure and relieve residual stresses, thus improving the material’s operating characteristics.

Custom treatments

Developed in collaboration with our clients’ technical departments, they adapt the final properties of the material to the highest standards of the market.

Innovation and sustainability<br />

go hand in hand

Since 2019, Trafilspec ITS has invested in new high efficiency heat treatment systems, resulting in significantly reduced energy consumption and environmental impacts, in line with ESG targets and our vision of responsible manufacturing.

All activities are supported by our in-house Laboratory, which continuously monitors all process parameters and verifies the metallurgical conformity of the treated materials.

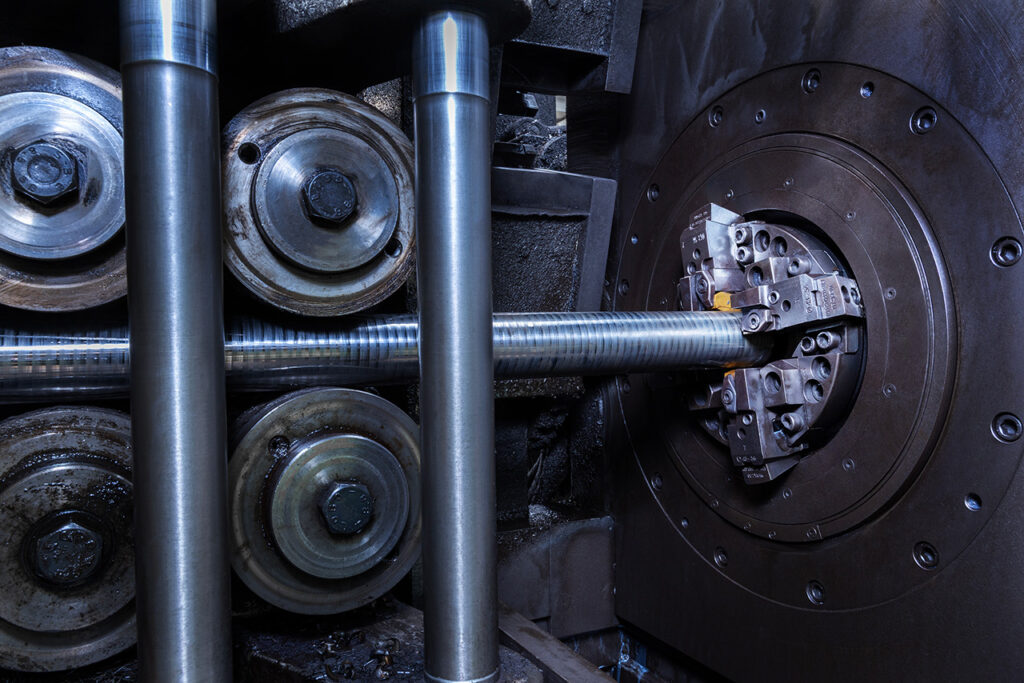

STC Furnace

With our installation of Europe’s first STC (Short Time Cycle) horizontal furnace, Trafilspec ITS has consolidated its specialisation in heat treatment and leadership in the drawn special steels industry.

The annealing system guarantees very high quality in terms of structural uniformity and a total lack of decarburization, thanks to our ability to constantly control the percentage of carbon in the atmosphere and ensure a perfectly uniform temperature at every point of the furnace.

The system is completely automated and controlled by a PLC, and is characterised by excellent flexibility, thus enabling us to run annealing, normalising and carbon re-establishment treatments for a variety of products including wire rods, bars, tubes and forged parts.