Super User

Cold working tool steels

Comparison with standard grades

UNI

AFNOR

DIN-W.Nr

BS

AISI-SAE

UNI

115CrV3AFNOR

-DIN-W.Nr

115CrV3 - 1.2210BS

36018AISI-SAE

L2UNI

100MnCrW4AFNOR

A35-590DIN-W.Nr

100MnCrW4 - 1.2510BS

4659AISI-SAE

O1UNI

100WV4AFNOR

-DIN-W.Nr

100WV4 - 1.2515BS

-AISI-SAE

-UNI

120WV4AFNOR

-DIN-W.Nr

120WV4 - 1.2516BS

-AISI-SAE

-UNI

X100CrMoV51KUAFNOR

Z100CDV5DIN-W.Nr

X100CrMoV5 1 - 1.2363BS

BA2AISI-SAE

A2According to: DIN 17350-UNI 2955

High speed steels

Comparison with standard grades

UNI

AFNOR

DIN-W.Nr

BS

AISI-SAE

UNI

HS 2-9-1-8AFNOR

Z110DKCWV 09-08-04-02-01DIN-W.Nr

S 2-10-1-8 1.3247BS

BM42AISI-SAE

M42According to: DIN 17350-UNI 2955

Constructional steels

Comparison with standard grades

UNI

AFNOR

DIN-W.Nr

BS

AISI-SAE

UNI

C60AFNOR

-DIN-W.Nr

C60 - 1.0601BS

060A62AISI-SAE

1060UNI

15CrNi6AFNOR

15CN6DIN-W.Nr

15CrNi6 - 1.5919BS

-AISI-SAE

4320UNI

18NiCrMo5*AFNOR

18NCD6DIN-W.Nr

-BS

815H17AISI-SAE

-UNI

20NiCrMo2AFNOR

20NCD5DIN-W.Nr

20NiCrMo2 - 1.6522BS

-AISI-SAE

8620* By request steels will be delivered with the addiction of lead (0.15 - O.30%) or checked sulphur (0.020 - 0.035%) for high speed mechanical works.

According to: UNI EN 10083 - 10084 - DIN 17200 - 17210

Hand and machine tool steels

Comparison with standard grades

UNI

AFNOR

DIN-W.Nr

BS

AISI-SAE

UNI

31CrV3AFNOR

-DIN-W.Nr

31CrV3 - 1.2208BS

-AISI-SAE

-UNI

38CrV4AFNOR

-DIN-W.Nr

-BS

-AISI-SAE

-UNI

59CrV4AFNOR

-DIN-W.Nr

59CrV4 - 1.2242BS

-AISI-SAE

-UNI

58CrMoV4AFNOR

58CDV4DIN-W.Nr

58CrMoV4 -1.7701BS

-AISI-SAE

8650Bearing steels

Comparison with standard grades

UNI

AFNOR

DIN-W.Nr

BS

AISI-SAE

UNI

-AFNOR

-DIN-W.Nr

100MnCr4 - 1.2127BS

-AISI-SAE

-UNI

-AFNOR

-DIN-W.Nr

X45Cr13 - 1.3541BS

-AISI-SAE

420 CUNI

-AFNOR

-DIN-W.Nr

X102CrMo17 - 1.3543BS

-AISI-SAE

420 CUNI

-AFNOR

-DIN-W.Nr

-BS

-AISI-SAE

S 2According to: DIN 17230-UNI 3097

Case hardening and nitriding steels

Comparison with standard grades

UNI

AFNOR

DIN-W.Nr

BS

AISI-SAE

UNI

16NiCrMo13AFNOR

16NCD13DIN-W.Nr

16NiCrMo12-6 - 1.6782BS

-AISI-SAE

-UNI

21CrMoV5-7AFNOR

21CDV5-7DIN-W.Nr

21CrMoV5-7 - 1.7709BS

-AISI-SAE

-UNI

30NiCrMo12AFNOR

(30NCD12)DIN-W.Nr

-BS

(826 M 31)AISI-SAE

A 723UNI

32CrMoV13AFNOR

32CDV13DIN-W.Nr

-BS

-AISI-SAE

-UNI

34NiCrMo16AFNOR

35NCD16DIN-W.Nr

35NICrMo16 - 1.2766BS

(835 M 30)AISI-SAE

-UNI

40CrMoV4-7AFNOR

40CrMoV4-6DIN-W.Nr

40CrMoV4-7 - 1.7711BS

-AISI-SAE

A 193UNI

40NiCrMo7AFNOR

-DIN-W.Nr

-BS

-AISI-SAE

4340Cold forging steel

Comparison with standard grades

UNI

AFNOR

DIN-W.Nr

BS

AISI-SAE

UNI

C35B2AFNOR

-DIN-W.Nr

-BS

-AISI-SAE

-UNI

34Cr4KBAFNOR

32C4DIN-W.Nr

34Cr4 - 1.7033BS

530H32AISI-SAE

(5132)UNI

36CrB4AFNOR

36CB4DIN-W.Nr

36CrB4 - 1.7077BS

-AISI-SAE

-UNI

38Cr1KBAFNOR

-DIN-W.Nr

(38Cr2 - 1.7003)BS

-AISI-SAE

-UNI

38Cr4KBAFNOR

38C4DIN-W.Nr

37Cr4 - 1.7034BS

530H36AISI-SAE

5135UNI

38CrB1KBAFNOR

38CB1DIN-W.Nr

-BS

-AISI-SAE

-UNI

38CrMoB1AFNOR

-DIN-W.Nr

-BS

-AISI-SAE

-UNI

41Cr4KBAFNOR

42C4DIN-W.Nr

41Cr4 - 1.7035BS

530H40AISI-SAE

5140UNI

45B2AFNOR

45B2DIN-W.Nr

45B2 - 1.5513BS

-AISI-SAE

-Stainless steels ferritic

Comparison with standard grades

UNI

AFNOR

DIN-W.Nr

BS

AISI-SAE

UNI

X8CrMo17AFNOR

Z8CD17-01DIN-W.Nr

X8CrMo17 - 1.4113BS

434S19AISI-SAE

434According to: UNI EN 10088 - DIN 17440

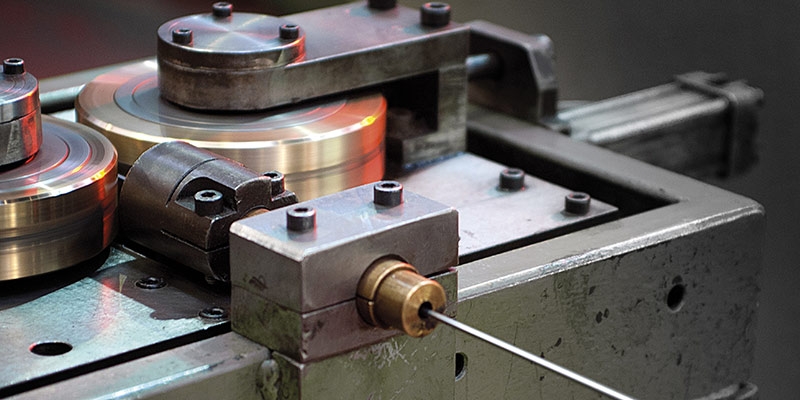

Drawing Bars

Shape

Dimensional range

Tolerance on size

Bars lenght

Bundle weight

Shape

Dimensional range

1,50 - 60,00 mmTolerance on size

h - k - j 7.......13Bars lenght

2.000 - 6.000 mmBundle weight

on demandShape

Dimensional range

1,27 - 36,00 mmTolerance on size

h - k - j 7.......13Bars lenght

2.000 - 6.000 mmBundle weight

on demandShape

Dimensional range

6,0 - 30,00 mmTolerance on size

h - k - j 7.......13Bars lenght

2.000 - 6.000 mmBundle weight

on demandShape

Dimensional range

1,50 - 15,00 mm*Tolerance on size

h - k - j 7.......13Bars lenght

2.000 - 6.000 mmBundle weight

on demandShape

Dimensional range

1,00 ≤ W ≤ 80,00 mm0,70 ≤ T ≤ 18,00 mm

Tolerance on size

h - k - j 7.......13Bars lenght

2.000 - 6.000 mmBundle weight

on demandShape

Dimensional range

14<=W<=267<=T<=13

Tolerance on size

h - k - j 7.......13Bars lenght

2.000 - 6.000 mmBundle weight

on demandShape

Dimensional range

4,00-16,00 mmTolerance on size

h - k - j 7.......13Bars lenght

2.000 - 6.000 mmBundle weight

on demand* Sharp or round edges

** Special profiles, according to drawing, upon request

Heat Treatment

The heat treatment changes the properties of the metallic materials in order to make following working operations easier. The phases of the heat treatment are: pre-heating, heating, maintenance and cooling. The parameters of the mentioned phases may change according to the heat treatment to be effected.

The heat-treatments effected by Trafilspec-ITS on its products are the following:

- globular annealing (GKZ / +AC): allows to get the cementite spheroidizing in order to reach minimum values of hardness and highest cold deformation.

- isothermal annealing (BG / +FP): mainly proper for cementation’s steels, allows to reach excellent machinability properties and a better micro-structure homogenising.

- stress relieving treatment (G / +A): allows to avoid tensions that may appear inside the wire after drawing operation.

- quenching and tempering (V / +QT): this is a quenching and tempering treatment, effected directly on raw material to give the material special mechanical properties of tensile strength and tenacity.

Download 2014 Catalogue

Download 2014 Catalogue