Super User

Ground bars

By grinding you remove material through grinding wheels and obtain high quality finishing on the surface.

Our production range for ground bars is the following.

Shape

Dimensional range

Tolerance on size

Bars length

Bundle weight

Shape

Dimensional range

2,00 - 110,00 mmTolerance on size

h - k - j 8Bars length

2.000 - 6.000 mmBundle weight

on demandPeeled bars

By peeling you remove the surface and the common defects that we can find on it (decarburization, cracks, foils, handling) through the use of cutting machine tools.

Our production range for peeled bars is the following.

Shape

Dimensional range

Tolerance on size

Bars length

Bundle weight

Shape

Dimensional range

16,00 - 120,00 mmTolerance on size

h - k - j 19Bars length

2.000 - 6.000 mmBundle weight

on demandDrawing coil to coil

By cold drawing you obtain a change of the hot rolled raw material through a plastic deformation, due to the action impressed by drawing dies.

Our production range for drawn coils is the following. Eventual special profiles can be produced upon request.

Shape

Dimensional range

Tolerance on size

Coils dimension

Coils weight

Shape

Dimensional range

1,50 - 28,00 mmTolerance on size

h - k - j 9.......11Coils dimension

500/1200 mm

500/1200 mmCoils weight

Min. 10 kgMax 1.000 kg

Shape

Dimensional range

0,70 - 18,00 mmTolerance on size

h - k - j 9.......11Coils dimension

400/900 mm

400/900 mmCoils weight

Min. 10 kgMax 1.000 kg

Trafilspec ITS

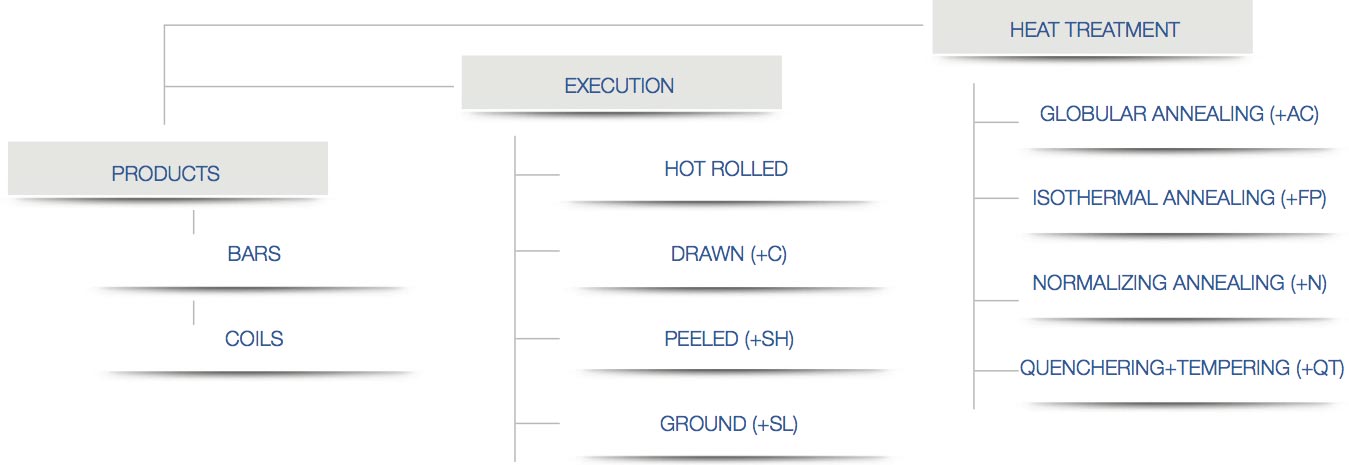

TRAFILSPEC ITS is specialized in the production of special steel

About Us

TRAFILSPEC ITS is specialized in the production of special steel.

Our technical know-how and high quality standards on both bars and coils, allow us to count our Company among the most important European Producers in the field of special steel cold processing.

Trafilspec-ITS is strongly specialized in the field of cold processing of special steels able to satisfy each customer's individual requirement, thanks to the versatility of the equipments used and to the flexibility of its organization.

Our modern and qualified equipments allow us to obtain high- quality and high-precision products both in bars (drawn and ground) and in coils (drawn) with round, square, hexagonal, flat and special profiles according to customers' specific drawing.

Further, first in Europe, we have installed the new furnace STC with horizontal chamber for globular annealing. This equipment assures high quality level in term of structure and guarantees the total absence of decarburization thanks to the capacity of controlling constantly the percentage of carbon inside the atmosphere and of assuring the same temperature in every zone of the furnace.

The full control of the working process, the versatility of the equipments and the flexibility of our organization allow us to answer and satisfy any customer's specification. That's the major asset of our production.

Trafilspec-ITS is equipped with the most modern equipments existing in commerce for non-destructive testing on both bars (drawn/ground) and drawn wires in coils.

According to the Company's strategies focused on quality improvements, we have integrated in our Group TRAFILTEST, an independent Company with the aim to control and guarantee the final quality of our products, thanks to a wide range of equipments.

Our quality system is accredited by RINA, in compliance with: ISO 9001:2008 - ISO/TS 16949:2009 and ISO 14001:2004.

The standard steel grades of our production are: bearing steel, tool steel, high speed steel, stainless steel, casehardening steel and cold working tool steel.

Certification

Trafilspec-ITS is certified ISO 9001:2008, ISO:TS 16949 and ISO 14001:2015 and ISO 45001:2018obtained thanks to a constant commitment to always offer a highly-qualified service.

A confirmation for the past and a guarantee for the future, another assurance for our customers.

STC Furnace

Thanks to the installation of the STC (Short Time Cycle) horizontal furnace used for special steel's heat treatment, Trafilspec-ITS reinforces its leadership inside the heat-treatment and drawing field of special steels.

The furnace assures high-quality level in term of structure and guarantees the total absence of decarburization, thanks to the possibility of constantly checking the carbon percentage inside the atmosphere and the capacity of assuring the same temperature in every zone of the furnace.

This equipment is completely automated and managed by PLC. Thanks to its high flexibility, it allows to realize soft annealing and normalizing treatments and carbon re-establishment on several products like wire rods, bars, tubes and forged parts.

Contacts

Trafilspec ITS S.p.A.

Via Cà Bianca, 2

22030 Castelmarte (CO) - Italia

Phone: +39 031.33561.1 r.a.

Fax: +39 031 622384

Capital € 12.700.000 i.v.

R.E.A. Como 298165

VAT 03140590138

e-mail: info@trafilspec.it

PEC: trafilspec@pec.confindustriacomo.it

Work with us

Become part of our team, we are always looking for new people to join our staff.

Non destructive control (CND)

Trafilspec-ITS is equipped with the most modern equipments existing in commerce for non-destructive testing on both bars (drawn/ground) and drawn wires in coils.

Controls effected by Trafilspec-ITS are the following:

- Defectomat control on bars and coils: non-destructive control effected through eddy-current equipment that allows detecting superficial cracks with transversal orientation, such as scabs, cracks, holes.

- Circograph control on bars: non-destructive control effected with equipment working with rotating probes that allows to detect superficial defects with longitudinal orientation as us rolling laps, tension cracks and drawing defects.

- non-cranking control: non-destructive control effected with magnetic-inductive equipment that allows to check the material exchange (o mixing) and the heat treatment.

- magnetoscope testing: non-destructive control effected with magnetic equipment that allows to detect superficial defects with transversal and longitudinal orientation.

Controls are effected according to European Norm UNI EN 10277-1:2000 or according to customer's specifications.

UNI EN 10277-1:2000 (products in bars)

Class of defect According to EN 10277-1

Diameter or key [mm]

Max. defect admitted

Max. % of bars with defects over the limit (1)

Shape (2)

Round

Exagon

Square

Class of defect According to EN 10277-1

1Diameter or key [mm]

up to 15from 15 to 100

Max. defect admitted

0.3 mm2% Diameter or key

Max. % of bars with defects over the limit (1)

4%Shape (2)

Round

+Exagon

+Square

+Class of defect According to EN 10277-1

2Diameter or key [mm]

up to 15from 15 to 75

from 75 to 100

Max. defect admitted

0.3 mm2% Diameter or key

1.5 mm

Max. % of bars with defects over the limit (1)

1%Shape (2)

Round

+Exagon

+(<= d 50 mm)

Square

+(<= d 20 mm)

Class of defect According to EN 10277-1

3Diameter or key [mm]

up to 20from 20 to 75

from 75 to 100

Max. defect admitted

0.2 mm1% Diameter or key

0.75 mm

Max. % of bars with defects over the limit (1)

1%Shape (2)

Round

+Exagon

-Square

-Class of defect According to EN 10277-1

4Diameter or key [mm]

up to 100Max. defect admitted

Free of defectsMax. % of bars with defects over the limit (1)

0.2%Shape (2)

Round

+Exagon

-Square

-(1) The last column shows the quantity of defective product that cannot be detected.

As well for controlled material this value cannot be zero because there are no controlling instruments granting absolute reliability. Trafilspec-ITS is anyway always engaged in the improvement of its own controlling devices to give customers the best reliability.

(2) + means that the shape is available in the corresponding classes, - means that the shape is not available in the corresponding classes.

Download 2014 Catalogue

Download 2014 Catalogue